Stock Rules Rules

NOTHING other than what is listed below is allowed

Follow general preparation, if a car is disqualified the Team is disqualified!

Officials decisions are FINAL!

YOU WILL HAVE 2 TIMES TO PASS INSPECTION OR YOU WILL BE DISQUALIFIED!

You must be checked in by 11 am or a penalty fee of $50 will be assessed.

Vehicles may be re-inspected at any time before, during or after the show

GENERAL PREPARATION:

TWO MAN EXTREME CLASS

Zach Dompier 509-989-5526

Format

Two drivers will be in the car one in the drivers seat and one in the passenger seat. The driver will have the steering column and the passenger will have the brake and gas pedal. The shifter can be ran by either participant. No pedals on the driver side will be allowed. The passenger may have a bar mounted to the dash bar or a dummy steering wheel to hold on to (this bar will not reinforce the car). No red cars will be allowed and both the drivers and passenger front doors of every car will be painted red to remind drivers they can't hit either front door.

General Rules

1. ALL RULES WILL BE FOLLOWED OR YOU WILL NOT RUN.

2. Any American make car can run with the following exceptions; No 2003 or newer FoMoCo frames, No 1970 or older Lincolns. No 1973 or older Chrysler Imperials or Imperial sub-frames, 4x4’s, ambulance, hearses, trucks, limousines, etc...

3. All drivers must sign the driver’s paperwork or they will not drive in the event.

4. Driver must wear a seat belt, helmet, FIRE SUIT JACKET (no more exceptions to the fire jacket rule).

5. All Drivers and Crew Members must attend the drivers meeting.

6. No hot rodding in the pits, keep it at an idle. This will be the quickest way to be DISQUALIFIED.

7. You are given 1 minute to make an aggressive hit. After 1 minute that particular car will be disqualified, not the team. You are only given 1 minute in total, not 1 minute to get started and 1 minute to hit.

8. No drivers are allowed alcohol - period. If you are wearing a driver’s band and drinking any form of Alcohol -YOU (if team event AND YOUR TEAM) WILL BE DISQUALIFIED.

9. Cars will be re-inspected before any prize money is paid out. The cars will be re-inspected by the Smash it staff only. Everyone else will stay back until cars are deemed to be legal.

10. There is a $250.00 protest fee, and you must be a driver in the main event to protest another car or team’s car. Driver must have cash in hand directly after the feature in order to protest. If the car is found to be illegal it will be disqualified and (if it is a team event the ENTIRE TEAM WILL BE DISQUALIFIED).

11. Any complaints that a driver has about another car prior to the start of the first heat will need to be addressed in the drivers meeting in specifics. If nothing is said, we don’t want to hear about it after the show.

12. Any questions, give me a call: Zach Dompier 509-989-5526 If these rules or a phone call to us does not say you can do it THEN DON’T. We can’t stress enough to call first.

13. Judges decisions are FINAL!!!

IF THE RULES DO NOT SAY YOU CAN DO IT YOU CANT!!!!!!!!!!

Car Preparation

1. No Fresh Paint or Undercoating on the frames at all. No buffing or grinding frames or bodies except where welding is specifically allowed in these rules.

2. All cars must be stock, unless modification is stated in the rules.

3. All glass, plastic, chrome, and interior must be removed from car before arriving to the derby.

4. All trailer hitches and braces must be removed.

5. Batteries must be moved to passenger front floorboard. They must be properly secured and covered.

6. You must have a number in Bright colors on each front door and must have a 15”x15” sign on the roof of your car with car number on it for judging and recognition of the car. You cannot use the roof sign to strengthen the car.

7. All cars must have working brakes when you cross the ramp. If the car is not able to exhibit the ability to stop it will not be inspected.

8. NO welding other than what is mentioned in this set of rules. If your car is found with any weld, other than what is allowed, and you refuse to fix it to the judge’s satisfaction, you and your car or team will not run!!

Frame Bumper

Bumpers are interchangeable. Any automotive bumper and bumper brackets may be used on any car, but no more than one set of bumper brackets may be used. You can weld bumper brackets or towers to the frame. You can weld bumper brackets and shocks to the bumper. You can weld shocks to shock towers. You can collapse shocks, and you can bolt the shocks to the towers with 1⁄2” bolt or less, and it must be done vertically. - ** No brackets are allowed to extend any further back than the first 10 inches of the frame. No brackets inside the frame at all!!

Instead of using bumper brackets you are allowed to use 1- 4” wide x 3/8” thick strap extending from your bumper down one side of the frame and cannot extend any further back than the first 10” of the frame. You are also allowed to wrap this strap around the front of the frame 4” to create an “L” shape this is to give you enough material to weld your bumper to the strap. Plate may be formed but it can not double at any point. Do not abuse this rule you will cut it.

You may not reinforce bumpers on the inside of the bumper. Only stock bumpers are allowed and only bumpers that came stock on cars may be used. You may trim bumper ends or fold them around. Welding the bumper skins (chrome to inner liner) is allowed. Weld them solid we do not want them coming off. No welding bumper to the body in any fashion, except on a 71-76 GM Wagon Rear bumper it may be welded to the body if still in factory location. Bumper height not to exceed 24” to the bottom of the bumper to the ground and much be a minimum of 14” from the ground to the bottom of the bumper or frame. Bumpers must be in stock location.

Front and rear bumpers may have 4 loops of wire from radiator support/trunk lid or deck (to sheet metal only do not go around core support bolts) to bumper (not frame). These cannot be placed in front of the radiator.

No manufactured bumpers are allowed other then a square tube 5x5x1/4" by 60" wide open ended on both sides. The bumper must be completely in front of the frame rails. No part of the bumper may extend back past the

front most part of the frame rails. Frame Shortening

You may shorten the front frame on a FoMoCo or GM on the front frame only. You may cut the frame off flush with the front edge of the body mount hole. If it is a weld on mount leave the remaining portion of the body mount in place. If you remove the body mount completely or relocate it you will not run.

Frame Welding

No rewelding of any factory seams is allowed.

Rust Repair

Call before fixing any rust on the frame. The rust can be cut out a piece cut exactly to the hole size may be butt welded in.

Frame Shaping

No frame shaping is allowed. Front Suspension

Tie Rods and Ball Joints - Tie rod tubes must remain stock. Do not re-engineer the way the steering components mount to the frame. Only stock car replacement ball joints and tie rod ends are allowed; no pickup or van tie rod ends.

A-Arms

A-arms may be welded or bolted down but may not be reinforced. If welded it may only use up to 1- 2x4x1/8” thick strap per a arm. This strap must weld to the a-arm and cannot extend farther forward or backward than 1” past the widest part of the a-aram. No modification of a arm mounts are allowed

Steering box

May be interchanged but must remain a stock box for a car that is legal in the class you are running. Pitman arms must remain stock or stock replacement

Idler Arm

Idler arm must remain stock or interchanged for an idler arm for that is off a car that is legal in the class you are running.

Hubs

Must remain stock for the spindle you are using no after market hubs or rotors. Brake calipers must remain stock for the stock spindles.

Spindles

Must be stock for a car that is legal in the class you are running, with no modifications.

Rear Suspension

Leaf springs must be stock and made of stock spring material, with a 1”stagger and no springs can be as long as the main leaf. You can only have a total of 9 leaf springs per side no thicker than 3/8" thick and no wider than 2 3⁄4” wide. The main leaf must be the top spring in the spring pack and leaf springs must go down from longest to shortest in minimum 1” stagger. You can re-clamp springs, 4 clamps per side with only 2 being homemade. Homemade clamps can’t exceed 2x4x1/4”. You can change coil springs to a stiffer spring, you can double the rear springs (they may be tied together in no more than two spots, do not weld them together), or put spacers in sagging coil springs to get your height, do not raise the suspension any other ways except what is listed above. You can bolt, wire, or chain coil springs to rear-end and frame to prevent springs from falling out, do not go through body as this would be another body mount. You may weld leaf spring mounting brackets to prevent them from becoming unbolted.

You can loop chain or wire (1 loop of 3/8” chain or 4 loops of #9 wires) from rear end to frame in 1 spot on each side, must go around frame, do not bolt the chain to the frame. We are going to allow you to weld the chain to the side of the frame, for your chains from the frame to the rear end, you can weld one link only to the side of the frame if you choose to weld the chain instead of wrapping it around the frame.

Rear-Ends

Use rear end of choice, nothing heavier than an 8 lug rear end. You can tilt rear end if you wish. Welded or posi-track highly recommended. Back braces are welcome. Braces may not extend more than 4 1/2” on the outer 10” of a stock size axle tube or 10” on the remaining housing.

Rear end control arms can be reinforced. They must start from a stock set but can be reinforced. They must attach in stock configuration for the suspension setup you are using. No Hybrid Setups.

Watts-Conversion are not allowed. No changing out rear package trays on frame.

You must use the factory brackets that came with the car you are running. No Relocating brackets on the frame.

Tires

Tires no bigger than 16 inch, No split rims, No studded tires. Foam filled or doubled tires are ok – we don’t want any flats!!! Valve stem protectors are ok. Tires may be screwed to rims. Wheel reinforcement is allowed as long as the wheel starts with a stock wheel, and the reinforcement stays within the factory bead. No bead locks in this class.

Motors and Transmission

Frame Cross Member – You are allowed to 4x6 plates on the frame engine saddle to attached your engine mounts to.

Motor -

1. Use motor of choice, motor must be in stock location.

Distributor Protectors are not allowed.

Mid Plates are not allowed.

Lower Cradles are allowed but must attached to a factory style engine mount, with rubber bushing, attached to frame. The factory engine mounts are the only way of tying the motor down.

PulleyProtectorsareanlolotwaelldo,wmeady.onlybelargerthan2"awayfromthePullys

Transmission Brace and Skid Plate are not allowed. No Carb Halos are allowed.

You may run an aftermarket bell housing but no other modifications may be to transmission. You are allowed to bolt it down to the cross member with 2 –5/8” bolts with 1.5” washers using the factory holes in the factory tail shaft cone. No transmission protectors or after market tail shaft cones.

Transmission Cross Member

You must run the transmission cross member in the stock location for the car you are building. You can weld 2” angle iron no thicker than 1/4”, no longer than 8” to the side of the frame to support the cross member. You must remove the stock mount if you run the angle iron. If you replace the cross member it can be no larger than 2x3”x1/4” square tubing or 2”x1/4” round tubing. The transmission cross member must be one piece and must be straight from side to side. The transmission cross member is the only method which the transmission may be tied in.

Body

Body Shaping

Minimal Body Shaping allowed, Must keep shaping clean. Call with questions

No body shaping is allowed.

Rust Repair

You can patch rust holes in sheet metal with sheet metal only. Do not cut rust out; weld 2” beyond rust. If your frame is rusted through, call for instructions on how to the fix the rust hole. DO NOT FIX IT

WITHOUT CALLING AND EXPECT US TO ALLOW YOU TO RUN IT. If you have to restub your

frame do so under the front doors but do not support the splice with the cross member. No ’03 and newer rear frames attached to ’02 and older front frames. No restubbing cars.

#9 Wire Rules

No #9 wire allowed in the window openings

You may run wire from frame rail underneath back of car, behind rear end with 4 loops of wire or 1 loop of 3/8 chain or cable. This may go around the frame, it may go through a factory frame hole, or you can weld 1 – 3/8 chain link to the side of the frame to run the wire through, but do not reinforce the frame with the chain link or you will cut it off. This wire may pass through the trunk floor if you choose.

Radiators

For mounting radiators you may use up to 4 – 1/2” all thread. This may pass thru the bottom of the core support. This must not pass thru upper core support. It may be attached to a 2”x 6” 1/8” flat steel and must be welded to the core support they must be outside the fan. No radiator guards allowed.

Body Mounts

Body mount bolts can be replaced with 5/8” bolts, body mounts can be replaced with steel or washers but must be 1” thick and have the same diameter as stock spacers. Bolts may extend through body and have up to a 1.5” washer on top, washers must be separate and cannot reinforce the frame. Bolts must be up inside of the frame. If you choose to use a body mount hole for you trunk ready bolt this does not have to be up inside frame, the plate can go on the bottom side of the frame and be no larger than 3”. if you choose to leave in the stock rubber pucks you must leave the metal cones inside the rubber puck. You must leave at least a 3⁄4 space if using the factory rubber spacer. Do not devise a way that enables you to suck them down tight.

Radiator support mounts can be removed, and you can suck the radiator support down solid. Absolutely no body mounts may be moved or added, do not shorten the front of your car and move back past the body mount hole as your car will not run. If you have to build core support spacers you may weld it either to the body or the frame mount, but only one side can be welded. Core Support Spacers cannot exceed 3” square material. . The front frame must not be shortened to far that the 1” all thread must pass through the factory stamped hole. The all-thread may only be welded to the side of the frame in this location.

Chrysler k-member can not be altered. Hoods and Front Clips

Hood must have at least a 12 inch square hole cut out in case of fire. Any holes in hood may be bolted back together with 3/8” or less bolts and 1.25” diameter washer no more than a total of 6 bolts allowed to pinch the hood sheet metal back together. You may cut multiple holes but do not exceed the 6 bolts. You are allowed 6 spots to hold the hood on; you must have a minimum of 4 tie down spots. You may have up to 1” all-thread, it may go from the hood to the frame, but must go through the front body mounts, this may be welded to the frame after it passes through the body mount but may not be nutted underneath the body mount if it is welded. All other tie down spots must be sheet metal to sheet metal only, and the hold down bolts cannot exceed 8” in length! All hood bolts must be placed outside the windshield bars. You may have plates for hood tie down, not to exceed 5x5x1/4”square or 6” x1/4” round.

Front core support cannot be moved back from its factory location. It must stay bolted to the fenders the same way that it came factory.

You may cut wheel wells for tire clearance. Fenders may be bolted back together with 5 -3/8” bolts or less with 1.25” diameter washers. No rolling your fenders and welding them. If you wrap or fold your fenders around the front of the core support do not exceed 4 – 3/8” bolts with 1.25” washers to bolt back to the core support of fender.

Windshield Bars and Firewall Firewall – Firewall may not be altered

Window Bars - For safety, all cars must have (2) windshield bars extending from the roof of the car to the firewall/dash, straps cannot be any larger than 3/8"x3" flat strap. If and only if you remove the firewall/dash completely between the straps you are allowed to connect these two bars. The removed part must be completely removed and must be as wide as the vertical bars. The horizontal bars connecting the two vertical bars cannot be any larger than 3/8"x3" straps. No more than 6" of strap material allowed on the roof and no more than 6" of strap material allowed on the firewall. Do not go over 6" on roof or firewall or you will cut.

Doors

You may weld your doors shut with nothing larger than 3” by 1/8” strap and must follow the door seam. Do not overlap strap or you will cut the strap off. You may fold tops of doors over and weld the outer skin and inner skin together but you are not allowed to add any material. If you chose must be tied shut in six locations using 1⁄2” bolts no longer than 6”, 3/8 Chain, or #9 wire. If we do not deem the car safe to compete you will add more fastening points.

You are allowed to add bracing to the exterior side of the drfirvoenrts door.sThis bracing must not stick any further

out than 2” from the door, and may not have any sharp edges. You are also allowed to carry the bracing up to

6” past the exterior door seam either forward or backward.This is strongly recommended to brace or skin your front doors.

Cage

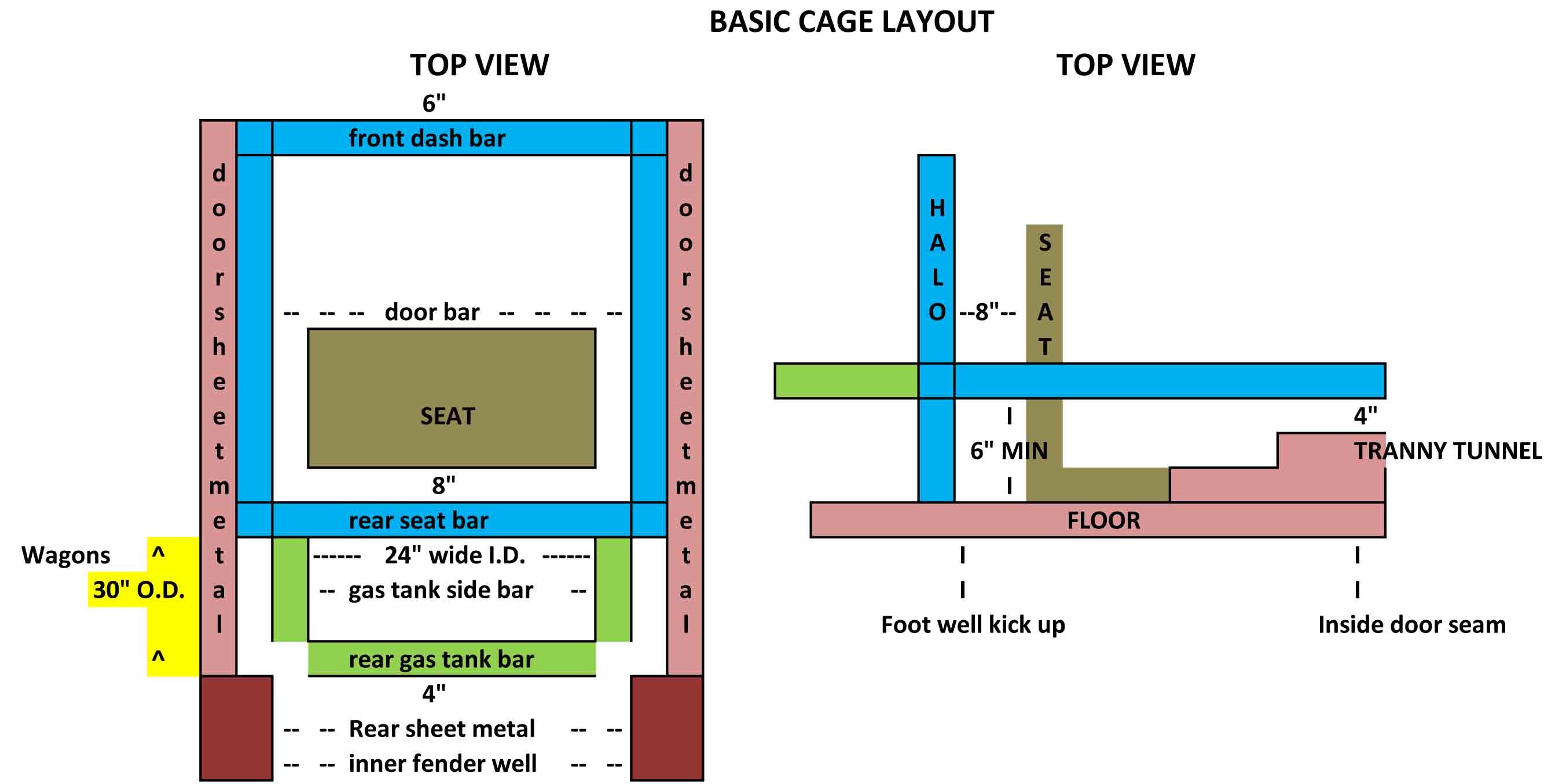

All cage material must be no larger that 6” od, unless specified for a specific rule smaller. It must also be a minimum of 4” off the floor everywhere except the down legs going straight down. No cage material may be within 6” of the firewall and be a minimum of 4” off the transmission tunnel.

You may weld a bar behind the seat from doorpost to doorpost, it can be an X do not connect directly to frame, and you may also have a single bar (with no extensions), across your dash area to replace your dash .You may run a bar connecting the dash bar and seat bar inside of the front doors only. You may weld two down bars from the cage to the frame vertically or to the floor to protect batteries and your feet. These down bars must remain behind the inside door seem and may only be welded to the top side of the frame. These bars cannot not exceed 2”x3”. You must have a roll loop behind the seat, which must be welded to the floor or frame and may be welded or bolted to the roof.

You may also weld a steering column to the cage. Back of cage including roll bar has to be placed: Ford and GM - a minimum of 5” in front of the center of the rear seat body mount. Mopars are allowed to run a 1” bolt with a 5" plate on both sides (frame and body) in the front most frame hole in the rear frame. You are then allowed to weld a kicker from the door bar and weld to the top of this plate. It can be a maximum of 2x3” square tubing. All Mopar cage material must be 5” forward from the center of this body mount hole other than the kicker explained prior. Some Mopars have a very tight passenger compartment and you may need to run the halo through the small back window, mainly Cordobas, call first.

Gas Tank Protector - You must run a gas tank protector. It cannot attach to anything other than your cage. It must be centered between your frame humps. It cannot exceed 24” wide. It can angle in from your roll over protection. It must be a full 3” away from rear sheet metal, which cannot be removed. The bracing must be 4” above all floor sheet metal, which cannot be removed, measured from the highest flat area of the floor in the rear seat area.

Fuel Tank, Oil Coolers, & Transmission Coolers

Original gas tanks must be removed. You must use a boat tank or well made fuel cell, and it must be properly secured and covered. Only metal tanks may be used. Fuel line must be secured and fastened properly. Keep away from exhaust. Place fuel cell behind driver’s seat or in the center of the car where the back seat use to be. No other source of gas inside the car at all. Engine coolers are allowed. These coolers cannot be placed to reinforce the car. No bolts may extend through the frame to create a body mount.

Trunks

You may weld your trunk lid shut 5 on 5 off using up to 3”x1/8” strap on the factory seam

You can fold hoods or trunk lid over. Do not slide your hood or trunk forward or back, trunk must remain on hinges. Trunk lids must be stock shape but may be folded in but keep it clean. Rear fenders must not be manipulated.

2-1” All-thread may go from the trunk lid to the frame or trunk pan, If it passes threw a body mount hole you must have a 1” spacer between the body and frame.

GM Wagons must remove all rear decking and seat components. All other rules above must be followed.

Pre Ran Cars are allowed but must only have four frame repair plates. Size of plates 4"x6" x1/4"

After the heats you are allowed a total of 6 frame repair plates. Use plates at your discretion but must have a 1" space between plates.

Pre Ran Cars must have entered a demolition derby heat, no driveway derby Pre Rans #Joker All other Pre Ran questions call Zach Dompier 509-989-5526

All cars are subject to reinspection before money is awarded.

SEE CAGE & CRADLE & GAS TANK PROTECTOR PIC’S BELOW

Sample Lower Saddle Cradle

Sample Transmission Adapter Plate

Gas Tank Protector Maximum